High performance (PTFE) coatings.

The High Performance or 'PTFE' Coatings section of Plastic Coatings Ltd applies technical coatings that contain materials such as PTFE or PolyTetraFluoroEthylene, FEP or Flourinated Ethylene Propylene Copolymer, Molybdenum and Graphite. These materials are normally applied to components where a non-stick, dry lubricant, low friction or release property is required.

PTFE coatings are often known by their familiar or trade names, Teflon ®, Xylan ®, Fluoroplastic, Flouropolymer or Fluorocarbon coating and they take the form of a liquid paint which is sprayed onto a substrate (metals, rubbers, plastics etc) that needs to be enhanced.

The liquid coating contains varying proportions of the technical materials, resins and other ingredients, exactly what is contained in each of the different coatings material recipes depends upon the desired coating film performance. Often it is not just the non-stick or low friction type of performance that is required, there will be a need for corrosion resistance, chemical resistance, humidity resistance, high and low temperature resistance & even colour coding for identification.

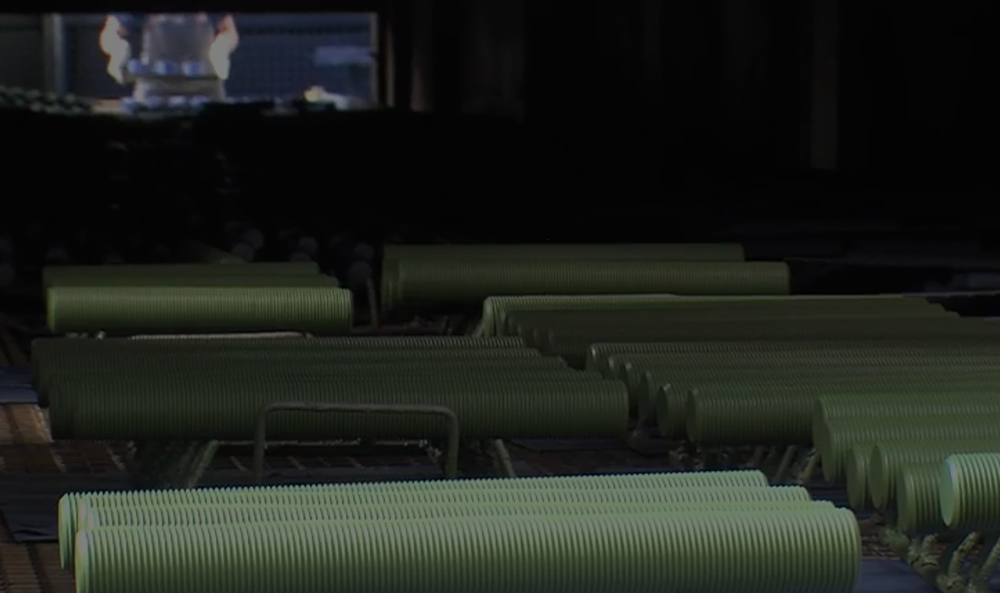

To apply a coating, the customer’s products / components are usually prepared by degreasing and gritblasting prior to being wet sprayed with the coating material. The resulting coating is then cured to a precise schedule in a properly ventilated industrial oven. The result is a high performance dry film coating with a thickness in the region of 15 microns to 35 microns depending upon the number of coats.

Customers may specify a grade to be non-stick for use in cookware or bakeware or for a food mould. Similar coatings are used in the moulding industries and in the Oil & Gas Industry for release agents in mould tools.

Dry lubricants are often used in Automotive or Aerospace & Defense for under bonnet / engine components, seat components and moving parts that will not subsequently need lubrication or servicing. Low friction coatings are used where perhaps two or more parts need to ‘slide’ smoothly together or within one another.

There are many material formulations within the range, some with quite specialist applications. Plastic Coatings Ltd are uniquely positioned in the supply chain and have excellent relations with the material manufacturers, this enables us to support formulation developments to suit specific requirements where a solution to a large project does not yet exist.

Our expertise in the application of these coatings can be verified by looking at the supply chains we currently work in and also the range of supply chain approvals we hold, including the Whitford QAC status.

Features can include:

- Non-Stick or excellent release properties

- Good Dry Lubricant

- Excellent Low Friction

- Thin coating which does not interfere with fit

- Heat resistance up to 300 degrees C

- Anti-Squeak

Typical components are:

- Domestic Cookware

- Sweet Moulds

- Baking Trays

- Plastic Moulding cavities

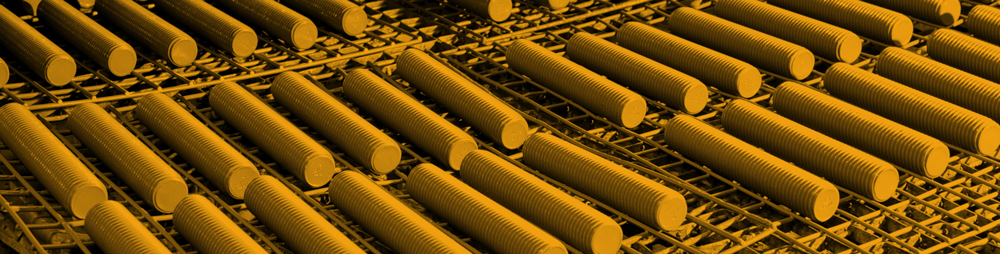

- Fasteners

- Rubber Seals

- Chutes

- Valves

- Shower components

- Hot Plates

- Medical equipment

Need a quote for an upcoming project?

Call or email us for a free quote.

-

- Customer approvals

-

- Other approvals