High performance coatings for the Energy industries.

Coatings have been used in Renewable Energy & More Traditional Energy Industries for many years. Plastic Coatings Ltd have vast experience in the application of specialist coatings for these industries. Due to our wide range of coating systems, our technical capabilities and our capacity we have been specified on many major projects.

Our coatings are used widely in sub sectors such as Oil & Gas (Subsea & Offshore), Petrochemical, Natural Gas, Wind Power, Solar Power, Hydroelectric Power, Nuclear Power etc.

Our range of 'PTFE' coatings are used for fasteners and other components (including valves, seals, gaskets, risers and fittings) and can improve corrosion resistance, reduce torque and eliminate galling as well as being available in range of colours to aid product identification.

We also offer a range of release coatings which are ideal for most moulding applications. In addition to coating application on new mould tools, we can strip old coatings, prepare and re-coat used moulds thereby extending the life of the tool. The benefits of release coatings for this application are the elimination of other manually applied release agents (such as sprayed and brushed on) and usually an improvement in process efficiency for our customers.

Other applications require that certain pipeline or pipe fittings and components used in Oil Exploration are dipped or coated in our Thermoplastic range of materials. The benefits of Thermoplastic coatings in this environment are the excellent corrosion resistance, chemical resistance, anti-flammability and low smoke and fume properties that the coatings offer.

The unique properties of thermoplastic materials offer the customer an opportunity to work the coating material in later operations. There are several applications where the applied coating is re-heated in the customer process and used a bonding agent for other materials and components to be robustly attached to the originally coated item. This is particularly common for filter screens and membranes.

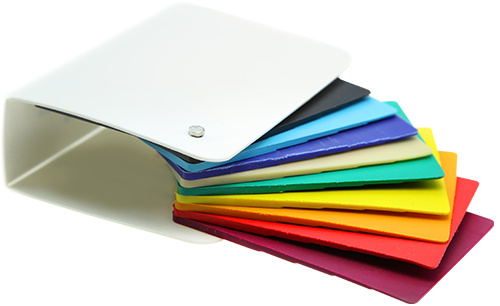

Range of colours available

We supply a wide range of plastic coatings colours. Bespoke colours are available via special order.

Typical components can be:

- Fasteners

- Extinguisher Bodies

- Backing Rings

- Pipeline Flanges and Fittings

- Mud Screens

Requirements for various finishes may be:

- Severe corrosion resistance

- Torque reduction

- Dry Lubrication

- Impact resistance

- Wear resistance

- High or low temperature resistance

- Chemical resistance

Need a quote for an upcoming project?

Call or email us for a free quote.

-

- Customer approvals

-

- Other approvals